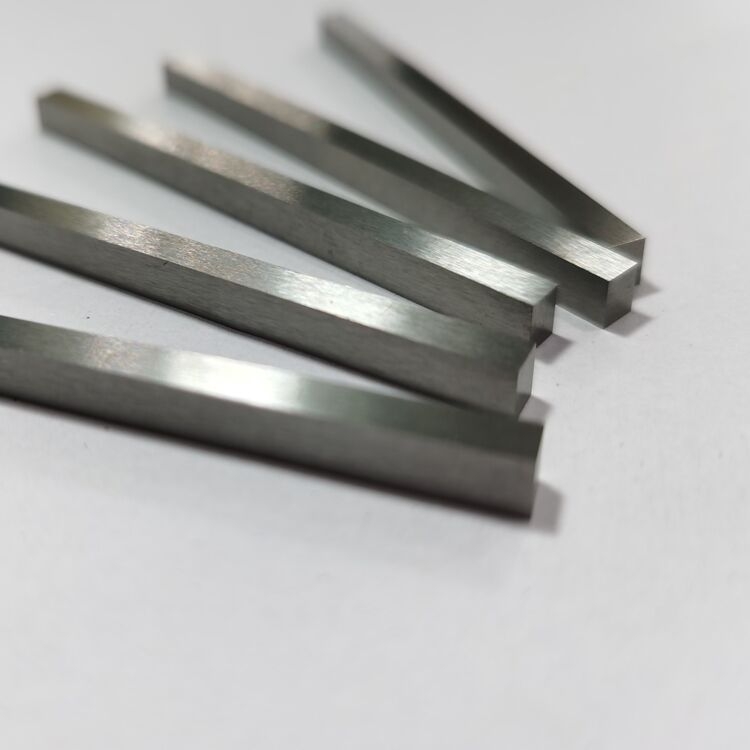

He mea hao i hana ʻia me kahi hui paʻakikī o kahi metala refractory a me kahi metala hoʻopaʻa ma o ke kaʻina hana metallurgy pauka. Loaʻa i ka carbide cemented kahi moʻo o nā waiwai maikaʻi loa e like me ka paʻakikī kiʻekiʻe, ke kūpaʻa ʻana i ka ʻaʻahu, ka ikaika maikaʻi a me ka paʻakikī, ke kūpaʻa wela a me ke kūpaʻa ʻana i ka corrosion, ʻoiai kona paʻakikī kiʻekiʻe a me ke kūpaʻa ʻana i ka ʻaʻahu, kahi e mau nei i ka loli ʻole ʻoiai ma ka mahana o 500 °C, he paʻakikī kiʻekiʻe nō ia ma 1000 ℃. Hoʻohana nui ʻia ka Carbide ma ke ʻano he mea hana, e like me nā mea hana huli, nā mea ʻoki wili, nā planers, nā drills, nā mea hana wili, a pēlā aku, no ka ʻoki ʻana i ka hao i hoʻolei ʻia, nā metala non-ferrous, nā plastics, nā fibers kemika, graphite, ke aniani, ka pōhaku a me ke kila maʻamau, a hiki ke hoʻohana ʻia no ka ʻoki ʻana i nā mea paʻakikī e mīkini e like me ke kila kūpaʻa wela, ke kila kila, ke kila manganese kiʻekiʻe, ke kila mea hana, a pēlā aku. ʻO ka wikiwiki o ka ʻoki ʻana o nā mea hana carbide hou i kēia manawa he mau haneli manawa o ke kila kalapona.

Ka hoʻohana ʻana o ka carbide sima

(1) Mea hana

ʻO Carbide ka nui loa o nā mea hana, hiki ke hoʻohana ʻia e hana i nā mea hana huli, nā mea ʻoki wili, nā planers, nā drills, a pēlā aku. I waena o lākou, kūpono ka tungsten-cobalt carbide no ka hana ʻana i nā ʻāpana pōkole o nā metala ferrous a me nā mea ʻole ferrous a me ka hana ʻana i nā mea ʻole metala, e like me ka hao i hoʻolei ʻia, ke keleawe i hoʻolei ʻia, bakelite, a pēlā aku; kūpono ka tungsten-titanium-cobalt carbide no ka hana lōʻihi o nā metala ferrous e like me ke kila. Chip machining. I waena o nā mea like, ʻo nā mea me ka nui o ka cobalt e kūpono no ka hana ʻana i nā mea ʻino, a ʻo nā mea me ka liʻiliʻi o ka cobalt e kūpono no ka hoʻopau ʻana. ʻOi aku ka lōʻihi o ke ola o nā carbides cemented ma mua o nā carbides cemented ʻē aʻe no nā mea paʻakikī e mīkini e like me ke kila kila.

(2) Mea hoʻoheheʻe

Hoʻohana nui ʻia ka carbide cemented no nā make hana anu e like me nā make kahaki anu, nā make punching anu, nā make extrusion anu, a me nā make pier anu.

Ma lalo o nā kūlana hana pale ʻaʻahu a i ʻole ka hopena ikaika, pono nā mea make poʻo anu Carbide e loaʻa i ka paʻakikī maikaʻi o ka hopena, ka paʻakikī haki, ka ikaika luhi, ka ikaika kūlou a me ke kūpaʻa ʻaʻahu maikaʻi. ʻO ka cobalt waena a me ke kiʻekiʻe a me nā papa alloy palaoa waena a me ka coarse e hoʻohana pinepine ʻia, e like me YG15C.

Ma keʻano laulā, kūʻē ka pilina ma waena o ke kūpaʻa ʻana o ka ʻaʻahu a me ka paʻakikī o ke carbide cemented: ʻo ka hoʻonui ʻana o ke kūpaʻa ʻaʻahu e alakaʻi ai i ka emi ʻana o ka paʻakikī, a ʻo ka hoʻonui ʻana o ka paʻakikī e alakaʻi pono ai i ka emi ʻana o ke kūpaʻa ʻaʻahu. No laila, i ke koho ʻana i nā papa alloy, pono e hoʻokō i nā koi hoʻohana kikoʻī e like me ka mea hana a me nā kūlana hana hana.

Inā maʻalahi ka māka i koho ʻia i ka haki mua a me ka hōʻino ʻana i ka wā hoʻohana, pono e koho ʻia ka māka me ka paʻakikī kiʻekiʻe; inā maʻalahi ka māka i koho ʻia i ka ʻaʻahu mua a me ka hōʻino ʻana i ka wā hoʻohana, pono e koho ʻia ka māka me ka paʻakikī kiʻekiʻe a me ke kūpaʻa ʻana i ka ʻaʻahu maikaʻi. . ʻO nā māka aʻe: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Mai ka hema a i ka ʻākau, emi ka paʻakikī, emi ka pale ʻana i ka ʻaʻahu, a piʻi ka paʻakikī; ma ke ʻano ʻē, ʻo ka ʻaoʻao ʻē aʻe ka ʻoiaʻiʻo.

(3) Nā mea hana ana a me nā ʻāpana pale ʻaʻahu

Hoʻohana ʻia ʻo Carbide no nā inlays ʻili kūpaʻa ʻole a me nā ʻāpana o nā mea hana ana, nā bearings pololei o nā wili, nā papa alakaʻi a me nā koʻokoʻo alakaʻi o nā wili waena ʻole, nā piko o nā lathes a me nā ʻāpana pale ʻē aʻe.

ʻO nā metala hoʻopaʻa he mau metala hui hao, ʻo ia hoʻi ka cobalt a me ka nickel.

I ka hana ʻana i ka carbide cemented, ʻo ka nui o nā ʻāpana o ka pauka mea maka i koho ʻia ma waena o 1 a me 2 microns, a kiʻekiʻe loa ka maʻemaʻe. Hoʻohui ʻia nā mea maka e like me ka lakio hoʻohuihui i kuhikuhi ʻia, a hoʻohui ʻia ka waiʻona a i ʻole nā mea hana ʻē aʻe i ka wili pulu i loko o kahi wili pōpō pulu e hoʻohui piha ʻia a wili ʻia. E kānana i ka hui ʻana. A laila, ua granulated ka hui ʻana, kaomi ʻia, a hoʻomehana ʻia i kahi mahana kokoke i ke kiko heheʻe o ka metala hoʻopaʻa (1300-1500 °C), ʻo ka pae paʻakikī a me ka metala hoʻopaʻa e hana i kahi hui eutectic. Ma hope o ka hoʻomaʻalili ʻana, ua hoʻolaha ʻia nā pae paʻakikī i loko o ka grid i haku ʻia me ka metala hoʻopaʻa a pili pono kekahi i kekahi e hana i kahi holoʻokoʻa paʻa. ʻO ka paʻakikī o ka carbide cemented e pili ana i ka nui o ka pae paʻakikī a me ka nui o ka palaoa, ʻo ia hoʻi, ʻo ke kiʻekiʻe o ka pae paʻakikī a me ka ʻoi aku ka maikaʻi o nā palaoa, ʻoi aku ka nui o ka paʻakikī. Hoʻoholo ʻia ka paʻakikī o ka carbide cemented e ka metala hoʻopaʻa. ʻO ke kiʻekiʻe o ka metala hoʻopaʻa, ʻoi aku ka kiʻekiʻe o ka ikaika flexural.

I ka makahiki 1923, ua hoʻohui ʻo Schlerter o Kelemania i 10% a 20% cobalt i ka pauka tungsten carbide ma ke ʻano he mea hoʻopaʻa, a ua hana i kahi hui hou o ka tungsten carbide a me ka cobalt. ʻO ka paʻakikī ka lua ma hope o ke daimana. ʻO ka carbide cemented mua i hana ʻia. I ka ʻoki ʻana i ke kila me kahi mea hana i hana ʻia me kēia hui, e pau koke ka ʻoki ʻana, a e haki pū ka ʻoki ʻana. I ka makahiki 1929, ua hoʻohui ʻo Schwarzkov ma ʻAmelika Hui Pū ʻIa i kahi nui o ka tungsten carbide a me ka titanium carbide compound carbides i ka haku mele mua, kahi i hoʻomaikaʻi ai i ka hana o ka mea hana i ka ʻoki ʻana i ke kila. ʻO kēia kekahi hoʻokō i ka mōʻaukala o ka hoʻomohala ʻana o ka carbide cemented.

Loaʻa i ka carbide sima kahi moʻo o nā waiwai maikaʻi loa e like me ka paʻakikī kiʻekiʻe, ke kūpaʻa ʻana i ka ʻaʻahu, ka ikaika maikaʻi a me ka paʻakikī, ke kūpaʻa wela a me ke kūpaʻa ʻana i ka corrosion, ʻoiai kona paʻakikī kiʻekiʻe a me ke kūpaʻa ʻana i ka ʻaʻahu, ka mea e mau ana i ka loli ʻole ʻoiai ma ka mahana o 500 °C, he paʻakikī kiʻekiʻe nō ia ma 1000 ℃. Hoʻohana nui ʻia ka Carbide ma ke ʻano he mea hana, e like me nā mea hana huli, nā mea ʻoki wili, nā planers, nā drills, nā mea hana wili, a pēlā aku, no ka ʻoki ʻana i ka hao hao, nā metala non-ferrous, nā plastics, nā fibers kemika, graphite, ke aniani, ka pōhaku a me ke kila maʻamau, a hiki ke hoʻohana ʻia no ka ʻoki ʻana i nā mea paʻakikī e mīkini e like me ke kila kūpaʻa wela, ke kila kila, ke kila manganese kiʻekiʻe, ke kila mea hana, a pēlā aku. ʻO ka wikiwiki o ka ʻoki ʻana o nā mea hana carbide hou i kēia manawa he mau haneli manawa o ke kila kalapona.

Hiki ke hoʻohana ʻia ʻo Carbide e hana i nā mea hana ʻeli pōhaku, nā mea hana mining, nā mea hana ʻeli, nā mea ana, nā ʻāpana pale ʻaʻahu, nā mea hoʻopailua metala, nā liner cylinder, nā bearings precision, nā nozzles, nā hoʻoheheʻe metala (e like me nā make uea, nā make bolt, nā make nati, a me nā ʻano hoʻoheheʻe paʻa like ʻole, ua hoʻololi mālie ka hana maikaʻi loa o ka carbide cemented i nā hoʻoheheʻe kila ma mua).

Ma hope mai, ua puka mai ka carbide sima i uhi ʻia. I ka makahiki 1969, ua hoʻomohala kūleʻa ʻo Suedena i kahi mea hana i uhi ʻia me ka titanium carbide. ʻO ke kumu o ka mea hana he tungsten-titanium-cobalt carbide a i ʻole tungsten-cobalt carbide. ʻO ka mānoanoa o ka uhi titanium carbide ma luna o ka ʻili he mau microns wale nō, akā i ka hoʻohālikelike ʻia me ka brand like o nā mea hana alloy, ua hoʻolōʻihi ʻia ke ola lawelawe e 3 mau manawa, a ua hoʻonui ʻia ka wikiwiki o ka ʻoki ʻana e 25% a 50%. I ka makahiki 1970, ua puka mai kahi hanauna ʻehā o nā mea hana i uhi ʻia no ka ʻoki ʻana i nā mea paʻakikī ke mīkini.

Pehea e sinter ʻia ai ka carbide cemented?

ʻO ka carbide cemented kahi mea metala i hana ʻia e ka metallurgy pauka o nā carbides a me nā metala hoʻopaʻa o hoʻokahi a ʻoi aku paha nā metala refractory.

Mnā ʻāina hana nui

Aia ma mua o 50 mau ʻāina ma ka honua e hana ana i ka carbide sima, me ka huina o 27,000-28,000t-. ʻO nā mea hana nui ʻo ʻAmelika Hui Pū ʻIa, Rusia, Suedena, Kina, Kelemānia, Iapana, United Kingdom, Palani, a pēlā aku. Ua piha loa ka mākeke carbide sima o ka honua. , he ikaika loa ka hoʻokūkū mākeke. Ua hoʻomaka ka ʻoihana carbide sima o Kina e hoʻokumu i ke ʻano i ka hopena o nā makahiki 1950. Mai nā makahiki 1960 a hiki i nā makahiki 1970, ua ulu wikiwiki ka ʻoihana carbide sima o Kina. I ka hoʻomaka ʻana o nā makahiki 1990, ua hōʻea ka huina o ka hana ʻana o Kina i ka carbide sima i 6000t, a ua hōʻea ka huina o ka hana ʻana o ka carbide sima i 5000t, ʻo ka lua wale nō ma hope o Rusia a me ʻAmelika Hui Pū ʻIa, ʻo ia ke kolu o ka honua.

Mea ʻoki WC

①Tungsten a me ka cobalt cemented carbide

ʻO nā mea nui ka tungsten carbide (WC) a me ka binder cobalt (Co).

Ua haku ʻia kona papa me "YG" ("paʻakikī a me cobalt" ma ka ʻōlelo Kina Pinyin) a me ka pakeneka o ka nui o ka cobalt maʻamau.

No ka laʻana, ʻo YG8 ke ʻano o ka awelika WCo = 8%, a ʻo ke koena he tungsten-cobalt carbide o ka tungsten carbide.

Nā pahi TIC

②ʻO ka carbide Tungsten-titanium-cobalt

ʻO nā mea nui ka tungsten carbide, titanium carbide (TiC) a me ka cobalt.

Ua haku ʻia kona papa me "YT" ("paʻakikī, titanium" ʻelua mau huapalapala ma ka prefix Pinyin Kina) a me ka awelika o ka titanium carbide.

No ka laʻana, ʻo YT15 ke ʻano o ka awelika WTi=15%, a ʻo ke koena he tungsten carbide a me ka tungsten-titanium-cobalt carbide me ka nui o ka cobalt.

Mea Hana Tantalum Tungsten Titanium

③ʻO ka carbide i hoʻopaʻa ʻia ʻo Tungsten-titanium-tantalum (niobium)

ʻO nā ʻāpana nui he tungsten carbide, titanium carbide, tantalum carbide (a i ʻole niobium carbide) a me cobalt. Ua kapa ʻia kēia ʻano carbide cemented he carbide cemented laulā a i ʻole carbide cemented honua.

Ua haku ʻia kona papa me "YW" (ka prefix phonetic Kina no "hard" a me "wan") me kahi helu moʻo, e like me YW1.

Nā ʻano hana

Nā Hoʻokomo Welded Carbide

Paʻakikī kiʻekiʻe (86 ~ 93HRA, like me 69 ~ 81HRC);

Paʻakikī wela maikaʻi (a hiki i 900 ~ 1000 ℃, mālama i ka 60HRC);

Kū'ē maika'i i ka abrasion.

ʻOi aku ka wikiwiki o nā mea hana ʻoki Carbide he 4 a 7 mau manawa ma mua o ke kila wikiwiki, a ʻo ke ola o ka mea hana he 5 a 80 mau manawa kiʻekiʻe. I ka hana ʻana i nā ʻōmole a me nā mea hana ana, ʻoi aku ka kiʻekiʻe o ke ola lawelawe ma mua o 20 a 150 mau manawa ma mua o ke kila kila alloy. Hiki iā ia ke ʻoki i nā mea paʻakikī ma kahi o 50HRC.

Eia nō naʻe, he palupalu ka carbide i hoʻopaʻa ʻia a ʻaʻole hiki ke mīkini ʻia, a he paʻakikī ke hana i nā mea hana hoʻohui me nā ʻano paʻakikī. No laila, hana pinepine ʻia nā pahi o nā ʻano like ʻole, i hoʻokomo ʻia ma ke kino mea hana a i ʻole ke kino hoʻoheheʻe ʻia ma ka hoʻoheheʻe ʻana, ka hoʻopaʻa ʻana, ka hoʻopaʻa ʻana i ka mīkini, a pēlā aku.

Pākuhi ʻano kūikawā

Ke hoʻoheheʻe ʻana

ʻO ke kālai ʻana o ka carbide simented sintering ʻo ke kaomi ʻana i ka pauka i loko o kahi billet, a laila e hoʻokomo i ka umu sintering e wela i kahi mahana (sintering temperature), mālama iā ia no kekahi manawa (paʻa manawa), a laila e hoʻolulu i lalo e loaʻa ai kahi mea carbide simented me nā waiwai e pono ai.

Hiki ke hoʻokaʻawale ʻia ke kaʻina hana sintering carbide cemented i ʻehā mau pae nui:

1: I ke kahua o ka wehe ʻana i ka mea hoʻokumu a me ka pre-sintering, hoʻololi ke kino sintered penei:

Ke wehe ʻia ka mea hoʻoheheʻe, me ka piʻi ʻana o ka mahana i ka wā mua o ka sintering, e palaho mālie a mahu paha ka mea hoʻoheheʻe, a ua kāpae ʻia ke kino sintered. He ʻokoʻa ke ʻano, ka nui a me ke kaʻina hana sintering.

Hoʻemi ʻia nā oxides ma luna o ka pauka. Ma ka mahana sintering, hiki i ka hydrogen ke hoʻemi i nā oxides o ka cobalt a me ka tungsten. Inā wehe ʻia ka mea hana i loko o ka vacuum a sintered, ʻaʻole ikaika ka hopena kalapona-oxygen. Hoʻopau mālie ʻia ke koʻikoʻi pili ma waena o nā ʻāpana pauka, hoʻomaka ka pauka metala hoʻopaʻa e hoʻōla a hana hou, hoʻomaka ka hoʻolaha ʻana o ka ʻili, a hoʻomaikaʻi ʻia ka ikaika briquetting.

2: Kahua sintering pae paʻa (800 ℃–mahana eutectic)

Ma ka mahana ma mua o ka ʻike ʻia ʻana o ka pae wai, me ka hoʻomau ʻana i ke kaʻina hana o ke kahua ma mua, ua hoʻoikaika ʻia ka hopena paʻa a me ka hoʻolaha ʻana, ua hoʻonui ʻia ke kahe plastik, a ua emi nui ke kino sintered.

3: Kahua sintering pae wai (mahana eutectic - mahana sintering)

Ke ʻike ʻia ke ʻano wai i loko o ke kino sintered, hoʻopau koke ʻia ka emi ʻana, a ukali ʻia e ka hoʻololi crystallographic e hana i ke ʻano kumu a me ke ʻano o ka metala.

4: Kahua hoʻoluʻolu (mahana sintering - mahana lumi)

I kēia pae, loaʻa kekahi mau loli i ke ʻano a me ka hoʻohuihui ʻana o ka metala me nā kūlana hoʻoluʻu like ʻole. Hiki ke hoʻohana ʻia kēia hiʻohiʻona e hoʻomehana i ka carbide cemented e hoʻomaikaʻi i kona mau waiwai kino a me ka mechanical.

Ka manawa hoʻouna: ʻApelila-11-2022